Sona Construction Technologies Pvt Ltd

16-05-2025

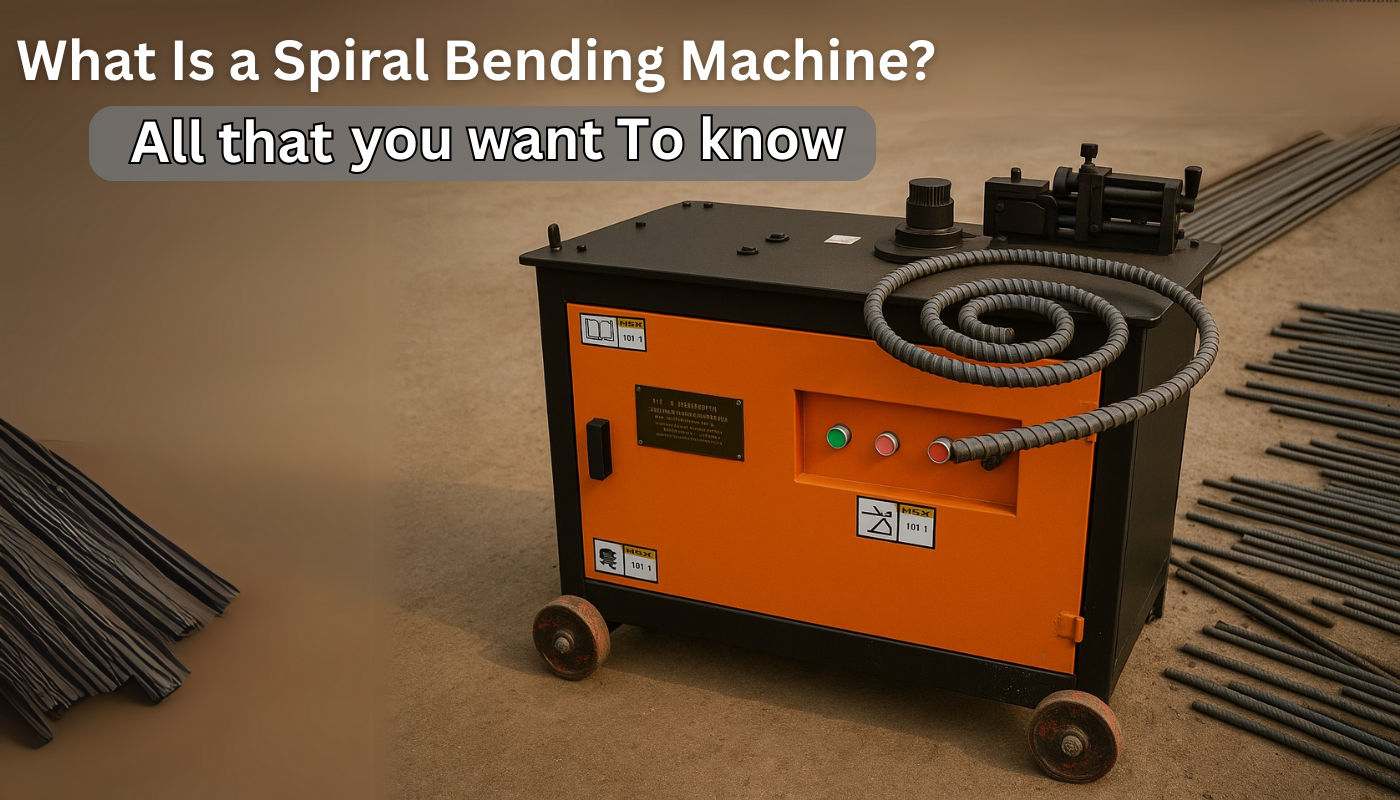

Ever seen those beautiful spiral staircases or curved metal handrails and wondered how they’re made? That’s where a spiral bending machine comes in. This machine helps shape metal pipes and tubes into smooth, spiral forms. It plays a big role in industries like construction, plumbing, and HVAC, making it easier to bend metal neatly without breaking or damaging it. Whether it’s for strong support structures or decorative pieces, this machine gets the job done right.

A spiral bending machine is a tool used to bend metal pipes or tubes into a spiral shape. Think of it like a tool that twists a straight pipe into a neat coil, just like a slinky. This type of bending is useful when you need metal to turn smoothly instead of in straight lines. It’s widely used to make parts for staircases, handrails, and even some parts of heating and cooling systems. The machine works with precision, so each bend is clean, even, and strong.

You might also hear this machine called by other names like:

Don’t get confused—they all refer to the same equipment. Different industries or regions may use different names, but the function remains the same: to bend pipes into spirals.

The working process of a spiral bending machine is simple to understand. The pipe or tube is placed into the machine, and the bending mechanism slowly rotates and presses it into a spiral form. This happens step by step so that the metal keeps its strength and shape.

The rotating spiral arm is the heart of the machine. As it moves, it bends the pipe or tube into a spiral. It does this with smooth, steady pressure, so the metal doesn’t crack or deform. This arm gives full control over how tight or wide the spiral should be, making it super useful for custom work.

Spiral bending machines are used across many industries. Here are the two most common areas:

In plumbing and HVAC, spiral pipes are used for water lines, heating ducts, and air ventilation systems. The spiral shape helps fit pipes into small or awkward spaces, which is especially helpful in buildings.

Architects and builders use spiral benders to create stunning spiral staircases, curved railings, fences, and even metal furniture. These shapes not only look great but also add strength and functionality to the design.

This is why professionals across industries trust spiral bending machines—they’re reliable, easy to use, and produce top-quality results.

Spiral bending machines can bend a wide range of metals and tubes, including:

As long as the material is ductile (can be bent without breaking), the machine can usually handle it. Different settings and tools are used depending on the thickness and type of metal.

If you work in metalwork, construction, or fabrication, a spiral bending machine could save you a lot of time and effort. It helps you create strong, smooth, and beautiful spiral shapes with ease. Whether you're bending pipes for function or for design, this machine is a smart investment. If your projects need precise and clean curves—this is the tool to count on.