A punching and shearing machine is a heavy-duty metalworking machine used in construction and fabrication industries for cutting, punching, and shaping steel plates, angles, and metal sections. It can quickly create holes, cut bars, and shear metal sheets with high precision, making it ideal for structural steel work, bridge fabrication, and industrial construction projects. These machines improve productivity, reduce manual labor, and ensure accurate metal processing for workshops and construction sites.

Punching and shearing machines are used to cut and punch steel beams, plates, and angles. They help prepare components for steel frame buildings. Common in industrial and commercial construction projects.

Used for punching holes and shearing metal parts for bridges and flyovers. Ensures accurate fabrication of girders and structural joints. Essential in heavy infrastructure development.

These machines shear metal sheets used in roofing, cladding, and wall panels. Provides clean and precise cuts for fitting and installation. Widely used in prefab and industrial shed construction.

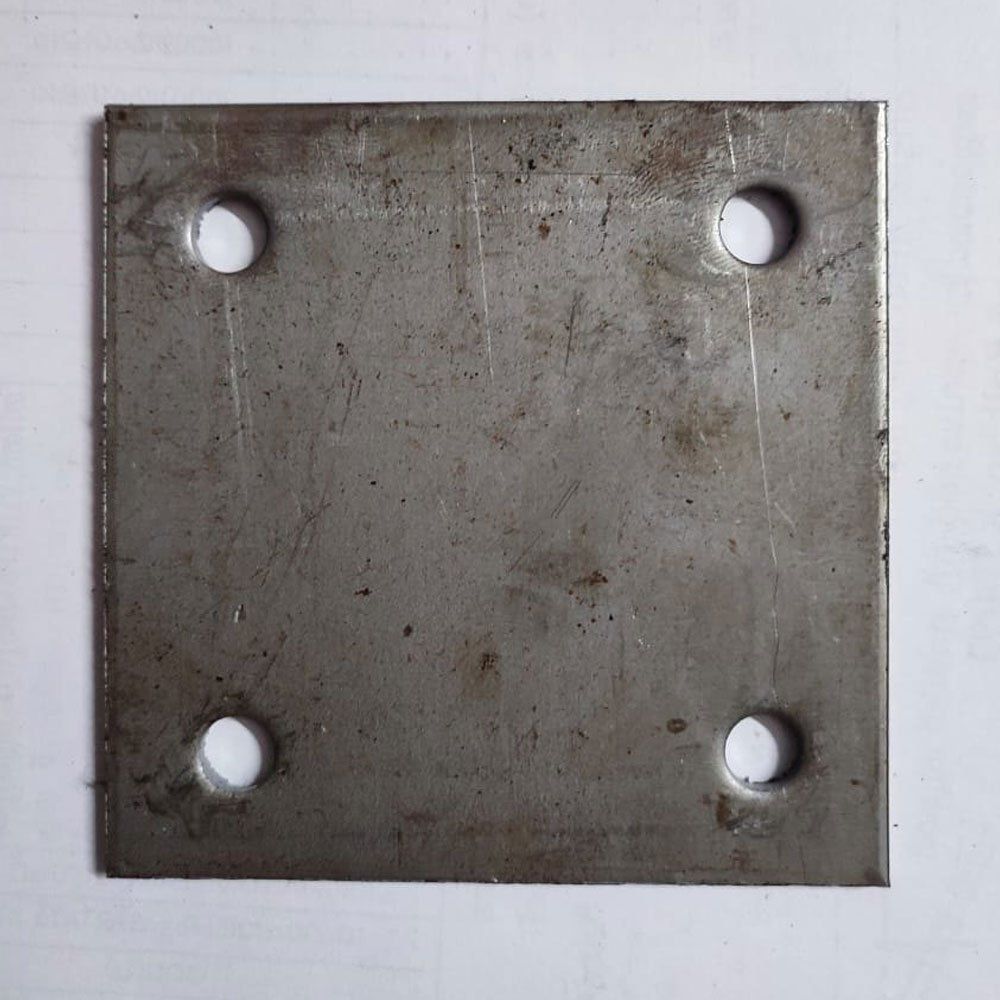

Punching machines create bolt holes in steel plates and sections. Supports strong fastening in structural assemblies. Improves speed and accuracy compared to manual drilling.

Used in fabrication workshops for processing steel bars, channels, and plates. Helps produce custom metal components for construction use. Reduces labor effort and increases production efficiency.

Get expert assistance for Punching and Shearing Machine . Our dedicated team is ready to help you find the perfect solution for your requirements.