Share:

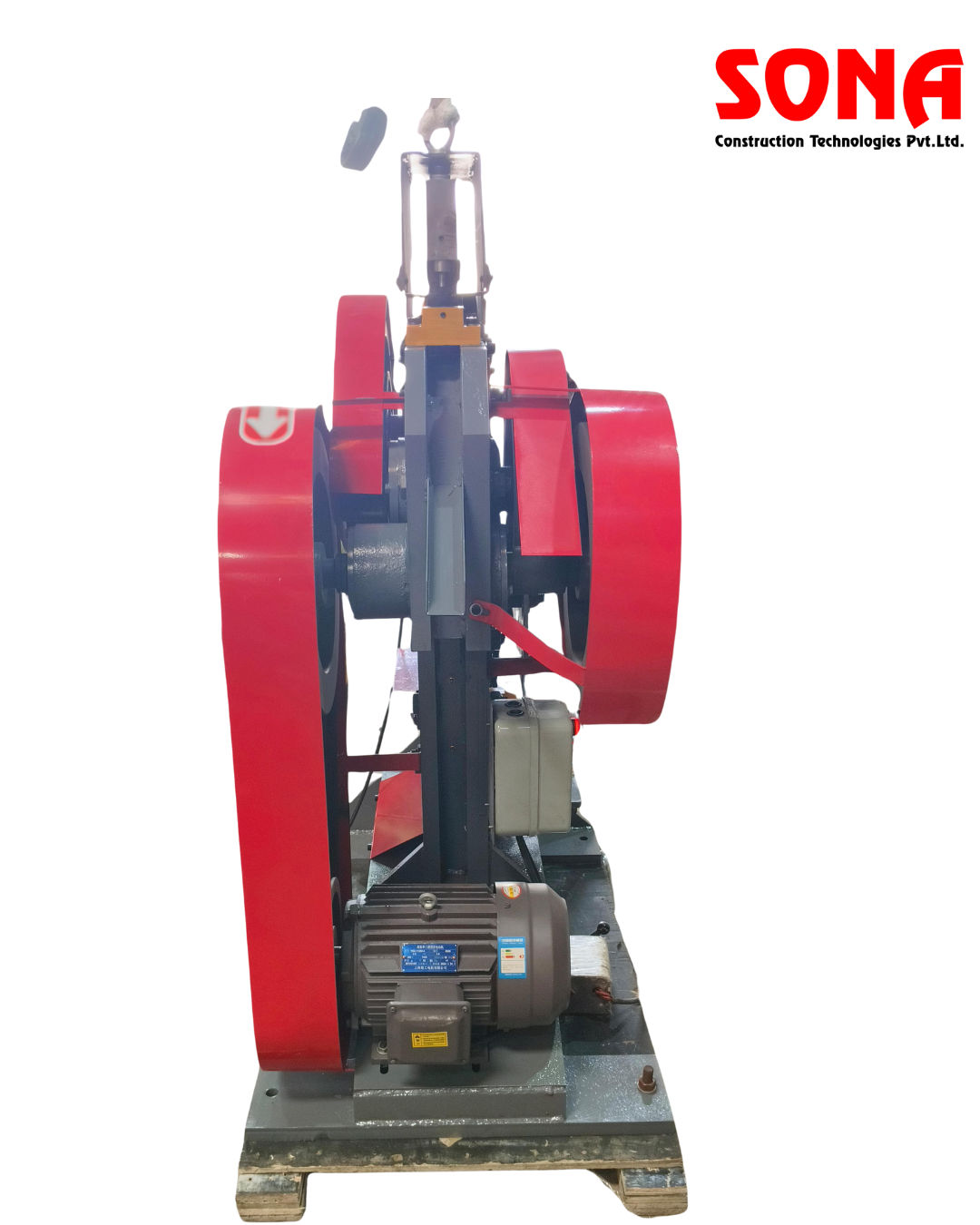

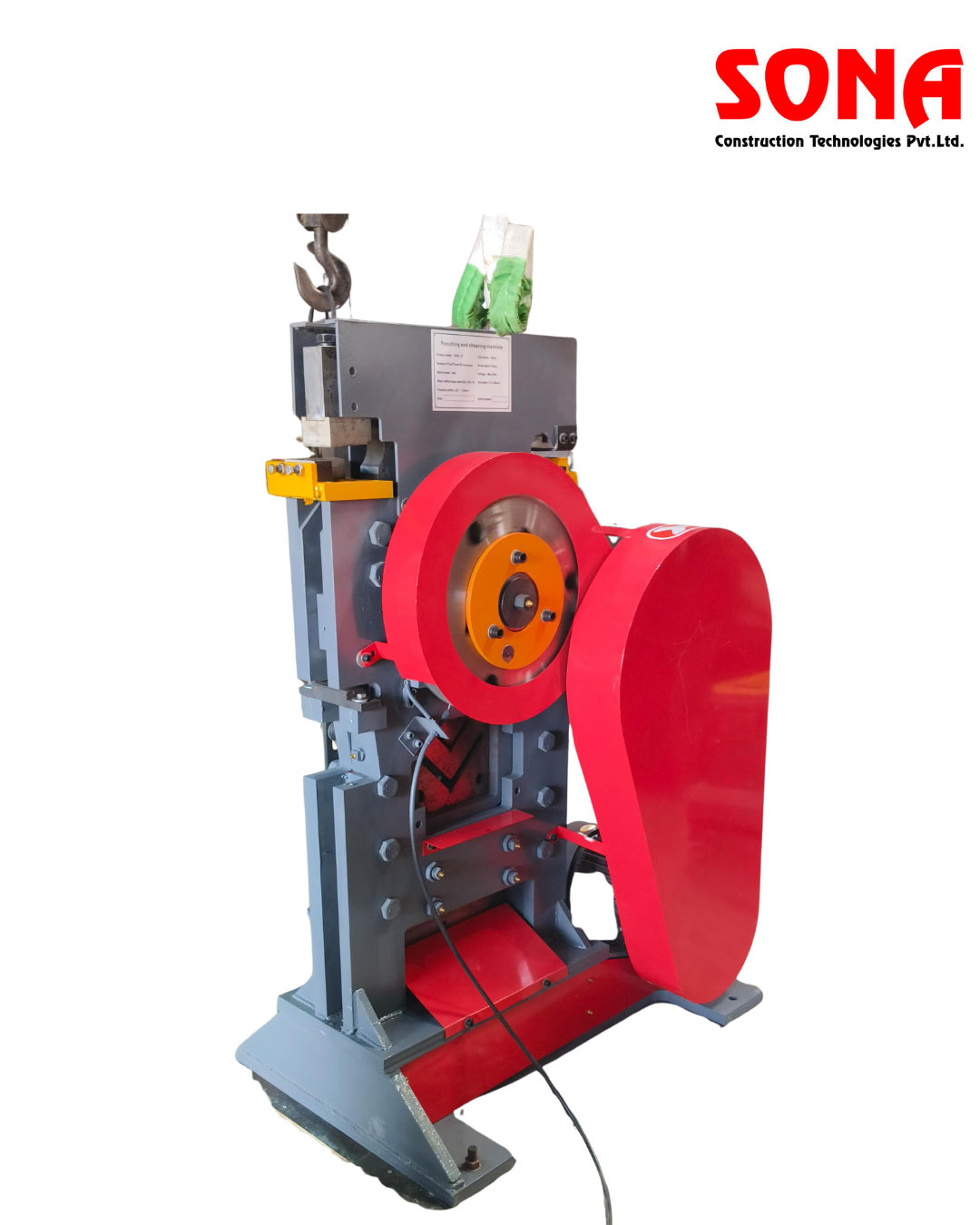

| Specification | Value |

|---|---|

| Model | QA32-12 |

| Shear Strength | 900kn |

| Tool Travel | 34mm |

| Stroke Times | 30T/min |

| Voltage | 380V |

| Motor power | 4kW |

| Throat Depth | 110mm |

| Iron Plate | δ 12*330mm |

| Punching ability | Ø32 (δ 12mm) |

| Shear ability | Angle steel 125*125*10 |

| Gross Weight | 942kg Approx. |

| Dimension | 1100*700*1500mm |

| Weight | 910kg |

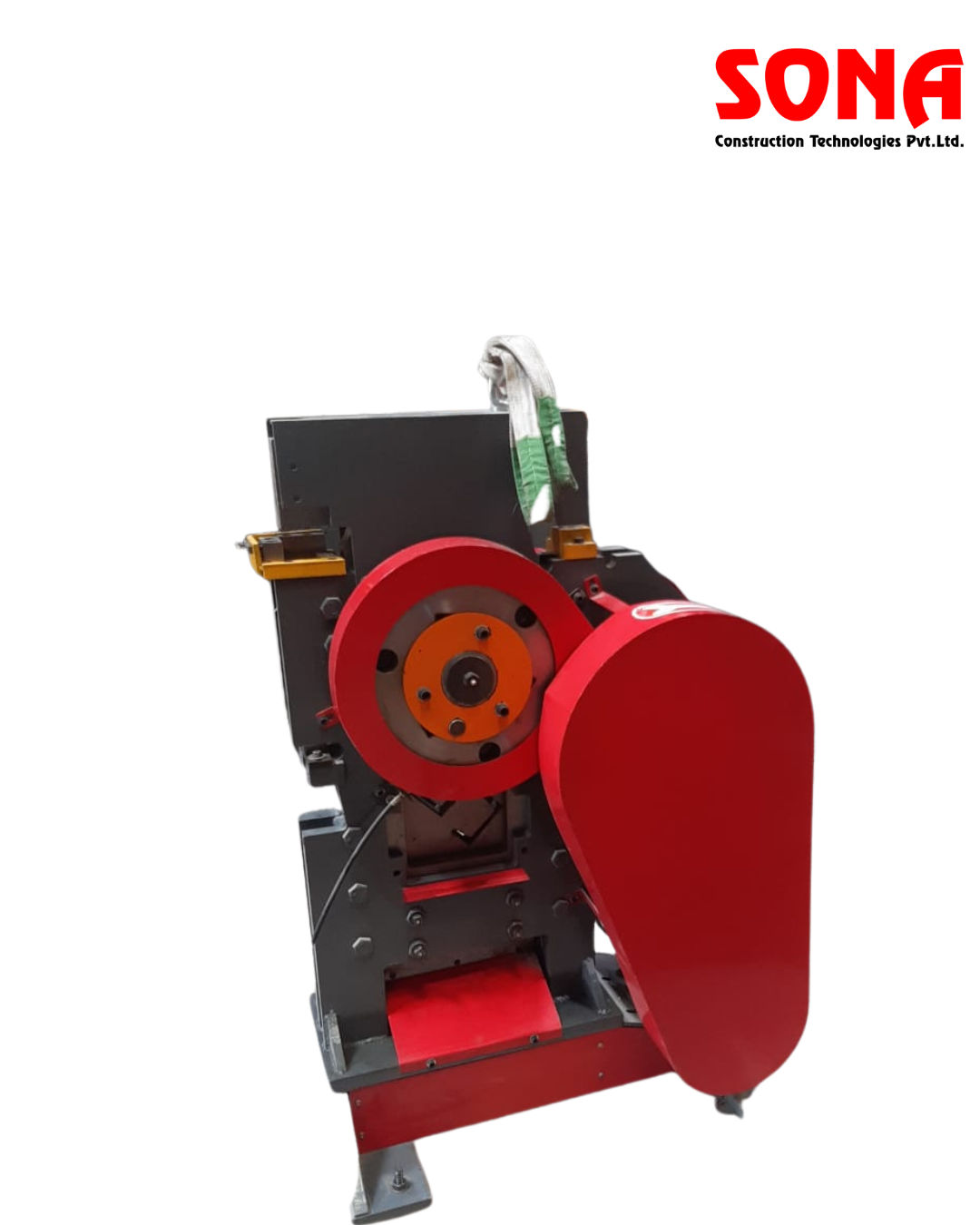

The QA32-12 Punching and Shearing Machine is a robust metal fabrication machine designed for punching and cutting steel plates, angles, and structural sections with high precision. It offers a powerful 900kN shear strength and comes with a strong 4kW motor power, making it ideal for heavy-duty industrial operations. Widely used in steel structure fabrication, bridge construction, and infrastructure projects, the QA32-12 ensures clean shearing and accurate punching for reliable structural assembly and faster workshop productivity.

Punching and shearing machines are widely used in structural steel fabrication for cutting and punching steel plates, angles, and channels. They ensure accurate shaping of components used in steel frame buildings and industrial sheds. This improves fabrication speed and dimensional accuracy.

In bridge and flyover construction, punching and shearing machines are used to process heavy steel sections for girders, joints, and load-bearing elements. They provide clean cuts and precise holes for high-strength connections. This supports safe and durable infrastructure development.

Punching and shearing machines are ideal for bolt hole preparation in steel plates and structural members. They produce uniform and accurately aligned holes for bolted assemblies. This ensures strong, secure, and reliable structural connections.

Industrial fabrication workshops use punching and shearing machines for high-volume metal processing operations. These machines reduce manual labor while increasing productivity and consistency. They are essential for efficient production of steel components.

For large infrastructure and metro projects, punching and shearing machines handle heavy-duty cutting and punching requirements. They are used in stations, tunnels, rail structures, and support frames. Their robust design ensures continuous performance under demanding conditions.