Sona Construction Technologies Pvt Ltd

09-05-2025

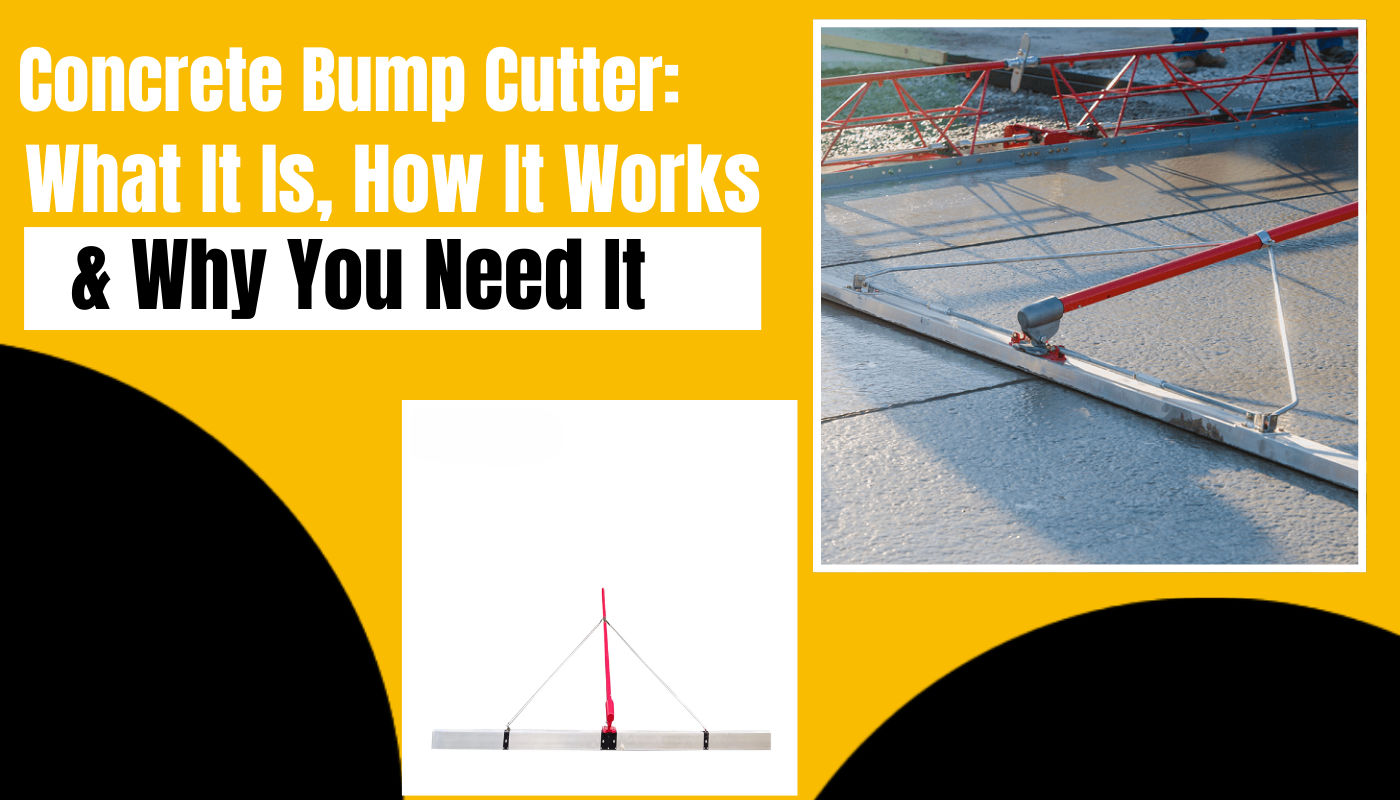

A concrete bump cutter is a tool used to level and smooth freshly laid concrete surfaces. When concrete is poured, it often ends up with bumps or uneven spots. This tool helps remove those high areas and fills in the low ones, creating a flat, smooth finish. Whether you're working on a factory floor, road, or warehouse slab, a bump cutter is essential for getting a professional-level surface.

There are two main types of concrete bump cutters: manual and machine-operated Manual bump cutters are simple tools, typically made of aluminum or steel, and used by hand. These are ideal for small projects and are widely available through suppliers like IndiaMART. On the other hand, automatic concrete bump cutters—like the ones from Shiva Construction—are heavy-duty machines designed for large-scale concrete leveling. These machines save time, require less labor, and give more consistent results. Whether you choose a manual concrete bump cutter or an automated bump cutter, the decision depends on your project's size and your budget.

The working process of a bump cutter tool is easy to understand. After concrete is poured and partially set, the cutter is dragged across the surface. As it moves, it trims the high spots and spreads the mix evenly over low spots. This results in a flat concrete surface that meets both visual and structural quality standards.Concrete surface leveling tools like bump cutters are often used right after screeding, especially when extra precision is needed.

Using a concrete surface bump cutter gives you many benefits:

You’ll find bump cutters in use across many concrete projects:

Wherever a level concrete surface is needed, a bump cutter is likely part of the job.

Yes. While there are other concrete surface leveling tools like screeds, trowels, and floats, bump cutters offer better results when precision is critical.

In India, top brands offering concrete bump cutter machines include:

These tools are made for professionals and builders who want reliable results on every pour.

These tools are made for professionals and builders who want reliable results on every pour.

In India, top brands offering concrete bump cutter machines include:

These tools are made for professionals and builders who want reliable results on every pour.

The bump cutter price in India depends on the type and size of the tool.

If you’re in construction or regularly level large concrete surfaces, an automatic bump cutter can be a good long-term investment.

To keep your bump cutter tool working well:

Basic maintenance extends the life of your concrete leveling equipment and saves money over time.

Here are some key points to consider when buying a concrete bump cutter:

Buying the right concrete finishing tool will improve your efficiency and the quality of your work.

If your goal is to get a flat, even, and professional concrete finish, then yes—a concrete bump cutter is the right tool for the job. From warehouses to roads, using this tool ensures better results, fewer surface problems, and floors that meet all the required standards.