Share:

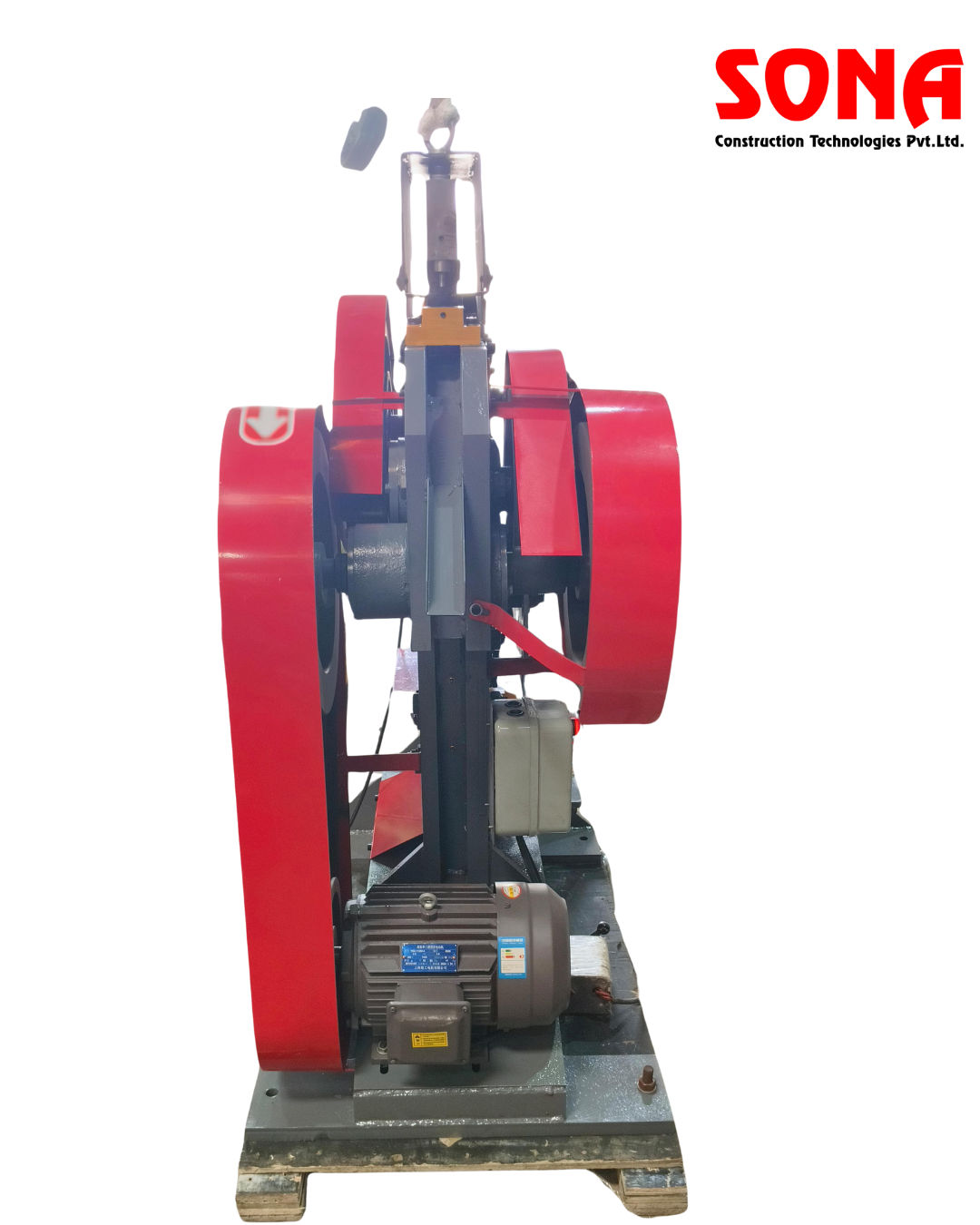

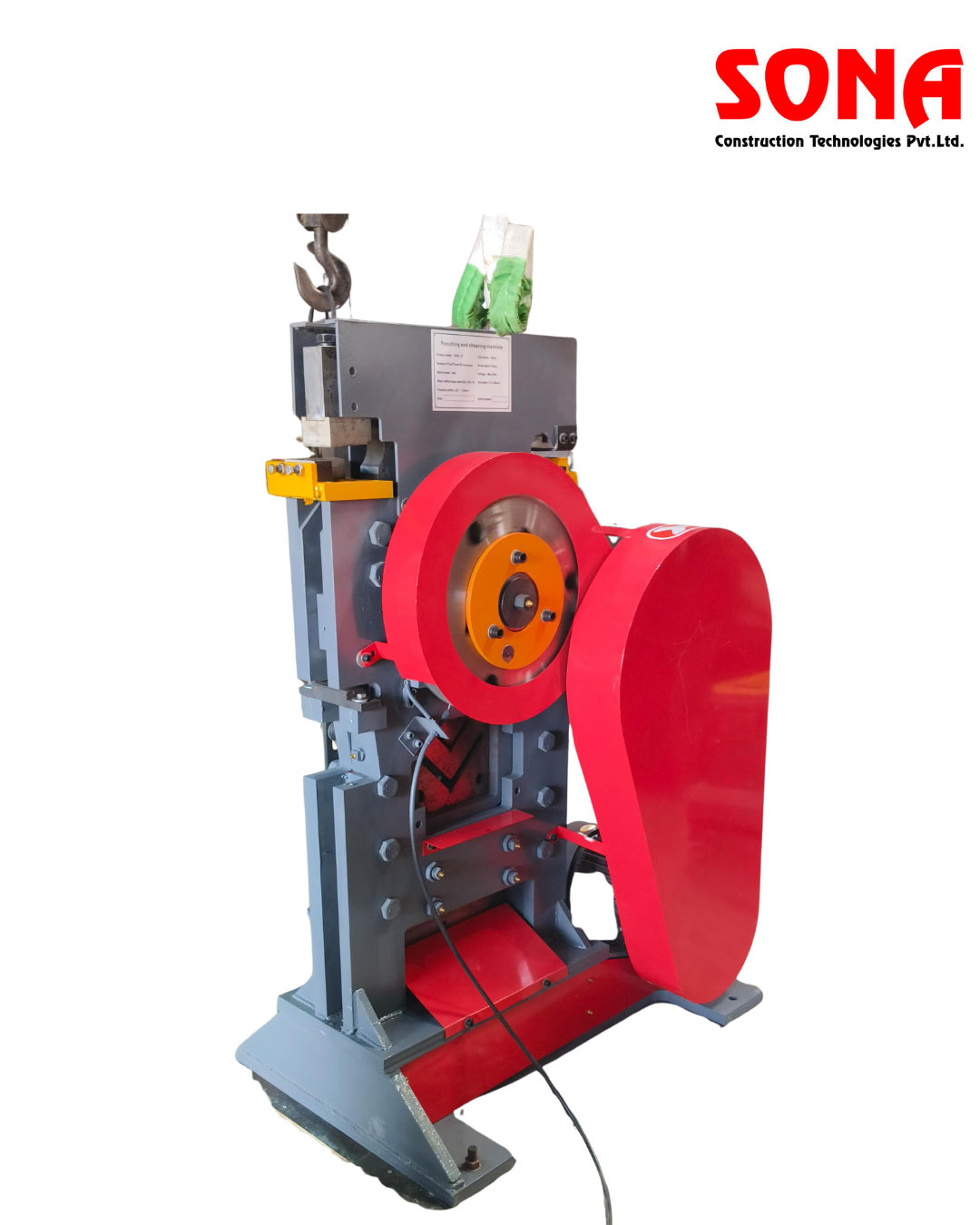

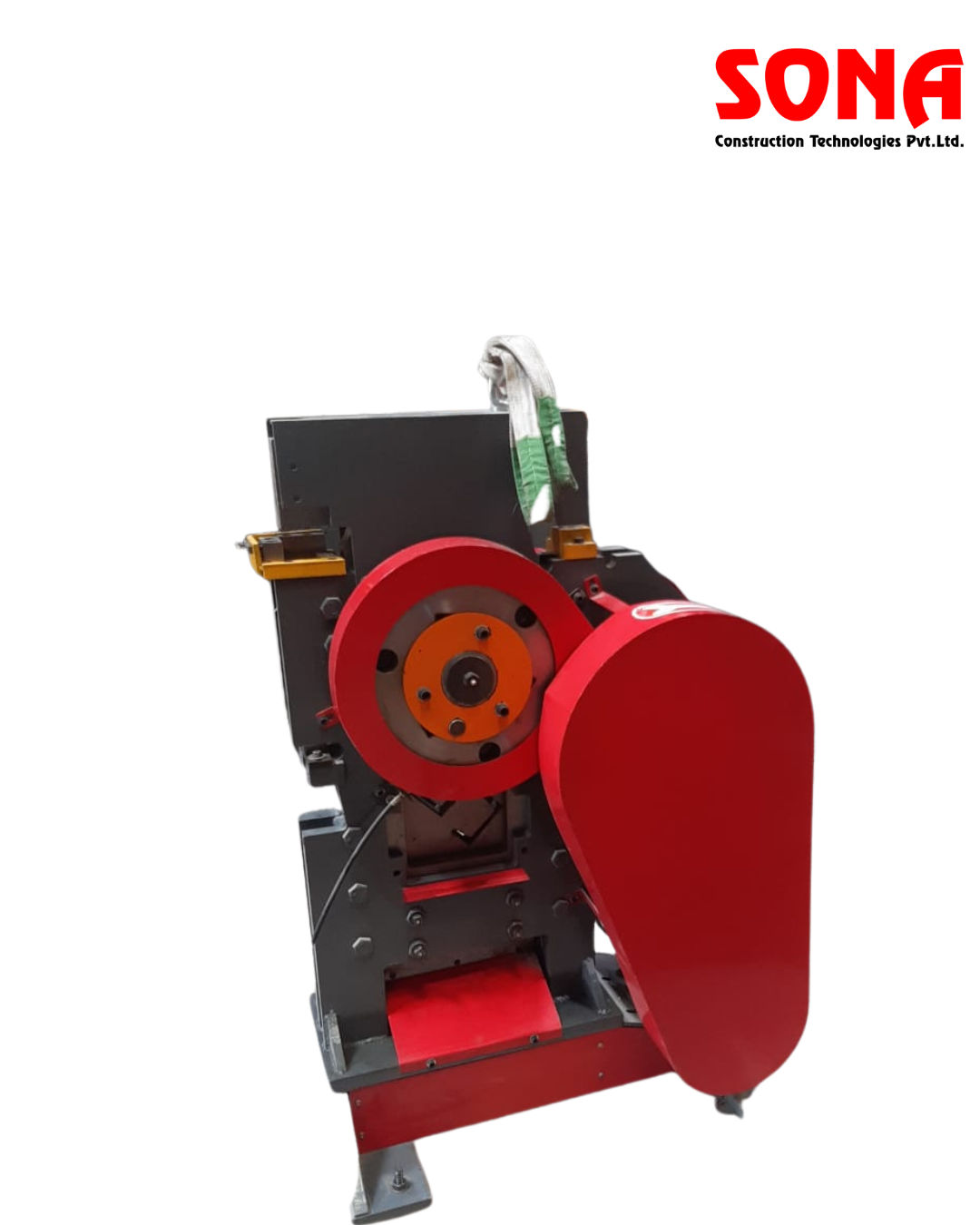

| Specification | Value |

|---|---|

| Model | QA32-12 |

| Shear Strength | 900kn |

| Tool Travel | 34mm |

| Stroke Times | 30T/min |

| Voltage | 380V |

| Motor power | 4kW |

| Throat Depth | 110mm |

| Iron Plate | δ 12*330mm |

| Punching ability | Ø32 (δ 12mm) |

| Shear ability | Angle steel 125*125*10 |

| Gross Weight | 942kg Approx. |

| Dimension | 1100*700*1500mm |

| Weight | 910kg |

The QA32-12 Punching and Shearing Machine is a robust metal fabrication machine designed for punching and cutting steel plates, angles, and structural sections with high precision. It offers a powerful 900kN shear strength and comes with a strong 4kW motor power, making it ideal for heavy-duty industrial operations. Widely used in steel structure fabrication, bridge construction, and infrastructure projects, the QA32-12 ensures clean shearing and accurate punching for reliable structural assembly and faster workshop productivity.

Structural Steel Fabrication: Used for punching and shearing steel plates and angles required in steel frame buildings and industrial sheds.

Bridge and Flyover Construction: Ideal for cutting and punching heavy steel components used in girders, joints, and load-bearing structures.

Bolt Hole Preparation: Commonly applied for creating accurate bolt holes in steel plates for fast and secure structural assembly.

Industrial Workshop Production: Widely used in fabrication yards for high-speed processing of metal sections, improving productivity and reducing manual effort.

Infrastructure and Metro Projects: Suitable for heavy-duty punching and shearing work in large infrastructure developments such as metro stations, tunnels, and rail structures.